Large Part Manufacturing • Value-Added Services • Fully Functional Assemblies

Recent Projects

PROJECT TITLE:

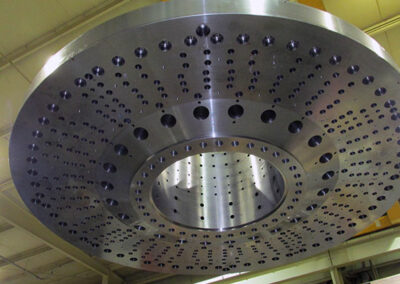

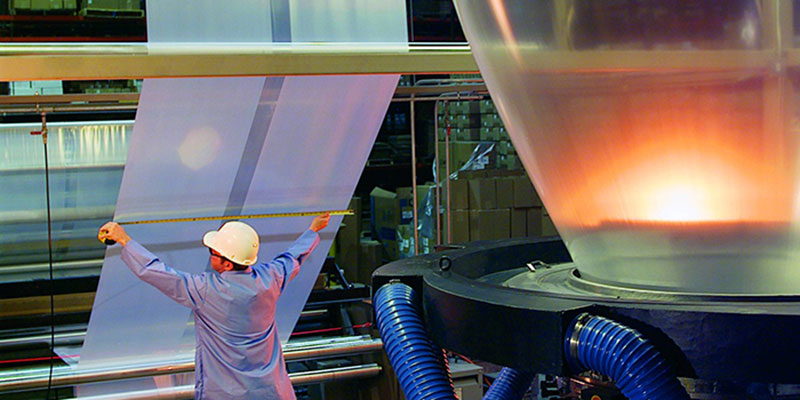

7 Layer Die for blown film

PROJECT DESCRIPTION:

Magna machined and assembled what we understand is currently the largest 7 layer blown film die in the world for one of the major OEM’s in the plastics industries. The job was a build to print project that required larger machining faculties than our customer had in house. We could manage this project ahead of the schedule needed by our customer because of the large numbers of machines we have in house to perform the work and our years of experience machining die parts.

CAPABILITIES APPLIED/PROCESSES

Primary:

- Vertical Turning

- Horizontal Turning

- Milling

- Gun Drilling

Secondary:

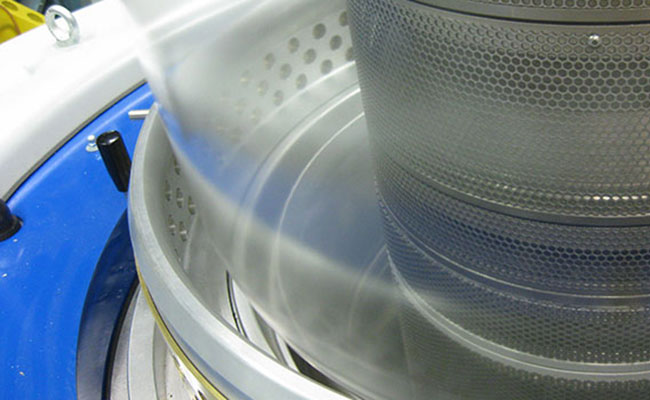

- Polishing

- Assembly

- Chrome Plating

EQUIPMENT USED TO MANUFACTURE PART

- CNC VTL’s

- CNC Horizontal Lathes

- CNC 4 Axis Mills

- CNC 5 Axis Mills

OVERALL PART DIMENSIONS

- Length: 130” Diameter

- Height: 60”

- Width: 130”

- Weight: 70,000 lbs Assembled

TIGHTEST TOLERANCES

- + -.0005

MATERIAL USED

- Alloy Steel, Stainless Steel

MATERIAL FINISH

- 6-32 Rms

INDUSTRY FOR USE

- Plastic Blown Film

IN PROCESS TESTING/INSPECTION PERFORMED

- Laser Tracker

- Faro Arm

VOLUME

- One unit

DELIVERY/TURNAROUND TIME

- 10 months

DELIVERY LOCATION

- Europe

STANDARDS MET

- ISO

SPECIAL FEATURES

- All plastics flow paths machined and polished to 6 Rms finish.

NOTABLE

Large turning and 5-axis milling

The client chose us based on our experience in machining these large parts.

Difficulties Overcome: The handling of this size highly polished parts is extremely difficult to avoid damage.

Positive Client Feedback: We received a letter of gratitude after the project was completed.

Special Feature of this Product: There are mutable layers of large diameter parts with very close tolerances that must stack up, and are then checked for concentricity after assembled that make it impossible for the average machine shop to do.

Finished Product:

- Programmers

- CNC Machinist

- Polishers and Assemblers

CONTACT US

Our experts are ready to discuss our capabilities and your needs.

Project Gallery

Click on a photo to view a larger image.

Completed Project Photography

© Magna Machine Co. All rights reserved.

Web site designed and maintained by Design-2-Part Web Design.