Large Part Manufacturing • Value-Added Services • Fully Functional Assemblies

Recent Projects

PROJECT TITLE:

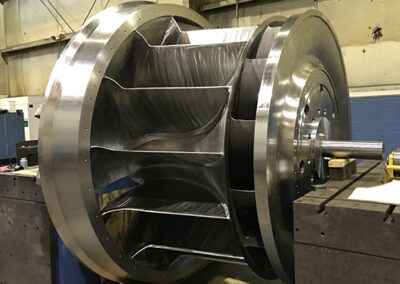

Leffel Runner

PROJECT DESCRIPTION:

The project was for the machining of a Runner for a hydraulic turbine that was used in the refurbishment of one of a unit that produces power at a dam in the Southern United States. Magna’s customer was the OEM that designs and builds Hydraulic Turbines and they were tasked with the project upgrade and refurbishment. Magna was chosen for the project because of our large turning and milling capabilities, as well as experience. This part was unique because of its size of over 100 inches in diameter and the critical nature of the part and time line. This part is the key to the turbine and as the water falls down through it the runner turns and is connect by a shaft to the generator to produce the power. Our customer was under a critical time line to have this built and back in service.

CAPABILITIES APPLIED/PROCESSES

Primary:

- Large CNC Vertical Turning and CNC Milling

Secondary:

- Assembly and trial fit up with mating parts

EQUIPMENT USED TO MANUFACTURE PART

- 130” VTL

- Large Horizontal Boring Mill

OVERALL PART DIMENSIONS

- Height: 80”

- Width: 101” Diameter

- Weight: 18000 Lbs

TIGHTEST TOLERANCES

- .001”

MATERIAL USED

- 304SS

MATERIAL FINISH

- 63 Rms

INDUSTRY FOR USE

- Power Generation

IN PROCESS TESTING/INSPECTION PERFORMED

- Inspection with Laser Tracker

VOLUME

- One unit

DELIVERY/TURNAROUND TIME

- 4 weeks

DELIVERY LOCATION

- United States

STANDARDS MET

- ISO

NOTABLE

The part is unique in its application and design and shows off our ability to perform on critical and high value parts

Our machines and experience gave our customer the confidence that we could meet the need and critical timeline.

Difficulties Overcome: The handling of the part was critical as many of the surface were flow path and had to be protected when turning it over and setting it up for machining operations.

Positive Client Feedback: They were very happy with our company for the flexibility to meet their critical schedule and the ability to work side by side with their people during the machining and trial fit up with other parts.

Special Feature of this Product: Because of the unique design of the part, it was very difficult to handle when setting up for machining. To turn the part over, two cranes had to be used in conjunction and the part was not allowed to be set directly on the formed buckets that extended past the areas to be machined.

Employee Roles: This part involved many different people.

Employees Involved:

- Project Management

- Manufacturing Engineers for Programming

- Machinist and Operators

- Assembly People

- Finishing Staff and Certified Welders

CONTACT US

Our experts are ready to discuss our capabilities and your needs.

Project Gallery

Click on a photo to view a larger image.

Completed Project Photography

Magna Machine Company

11180 Southland Road

Cincinnati, OH 45240

Ph: 513.851.6900

© Magna Machine Co. All rights reserved.

Web site designed and maintained by Design-2-Part Web Design.