Large Part Manufacturing • Value-Added Services • Fully Functional Assemblies

Recent Projects

PROJECT TITLE:

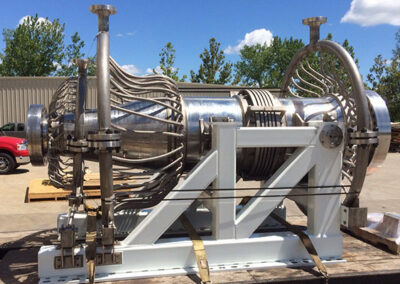

Cell A20 Plenum

PROJECT DESCRIPTION:

Magna Machine was contracted to build a portion of the new test cell for GE Aviation. The 2-walled pressure vessel is designed to mimic the flow of air through the compressor, thus allowing GE to test various components under real life conditions inside the engine. This test system runs at twice the pressure and temperatures as existing test systems.

CAPABILITIES APPLIED/PROCESSES

Primary:

- Turning

- Welding

- Milling

Secondary:

- Deep Grooving

- Assembly

EQUIPMENT USED TO MANUFACTURE PART

- CNC VTL’s

- Large Mills

- Welding

OVERALL PART DIMENSIONS

- Length: 160”

- Height: 96”

- Width: 72”

- Weight: 11,000 lbs

TIGHTEST TOLERANCES

- ±.001

MATERIAL USED

- Inconel 625 (aka Haynes 625)

MATERIAL FINISH

- 32

INDUSTRY FOR USE

- Aviation test facilities

IN PROCESS TESTING/INSPECTION PERFORMED

- FPI

- X Ray

- Faro Arm

VOLUME

- One unit

DELIVERY/TURNAROUND TIME

- 13-16 Months with Concurrent Design & Manufacturing

DELIVERY LOCATION

- Cincinnati, Ohio

STANDARDS MET

- Welds per ASME Pressure Code

- X-Ray per ASME

SPECIAL FEATURES

- This unit.

NOTABLE

This program was a multimillion dollar contract which required Magna to manage everything from material procurement through final inspection. It also demonstrated our willingness to work with customers who are concurrently designing and building a component.

The client chose us based on our proximity to GE and our eagerness to work with them while they were still completing the job.

Difficulties Overcome: Material delivery, deep grooves, welding.

Positive Client Feedback: Component work wonderfully.

Special Feature of this Product: Deep grooves, X Ray welded Joints

Finished Product:

- Programmers

- Engineering

- VTL Machinists

- HBM Machinists

- Welders

- Weld Inspectors

CONTACT US

Our experts are ready to discuss our capabilities and your needs.

Project Gallery

Click on a photo to view a larger image.

Completed Project Photography

Magna Machine Company

11180 Southland Road

Cincinnati, OH 45240

Ph: 513.851.6900

© Magna Machine Co. All rights reserved.

Web site designed and maintained by Design-2-Part Web Design.