Recent Projects

PROJECT TITLE:

Facility for Rare Isotope Beams: http://www.frib.msu.edu

PROJECT DESCRIPTION:

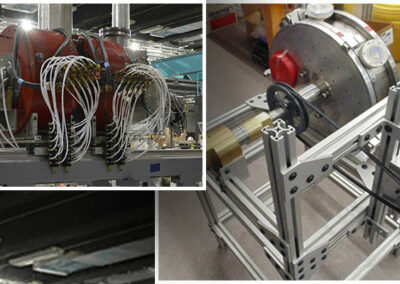

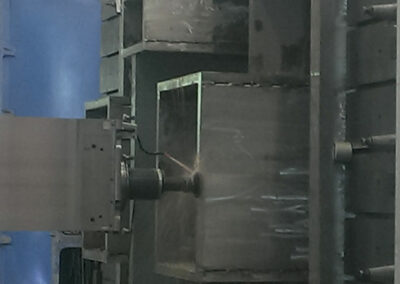

Magna-Machine was sub-contracted to machine 3 large vessels as well as several sub-assemblies / lids for MSU for the Rare Isotope Beam Facility to explore new and unexplored regions of the nuclear chart.

Wedge Vessel, Target Vessel and Beam Dump

CAPABILITIES APPLIED/PROCESSES

Primary:

Large machining in Super Bay

Secondary:

- Laser Inspect

- De-burr/Polish

EQUIPMENT USED TO MANUFACTURE PART

- Union PCR 160 Ram Type CNC

OVERALL PART DIMENSIONS

Wedge Vessel

- Length: 19’ 3/8”

- Height: 14’ ½”

- Width: 10’ 3/8”

- Weight: Approximately 85,000 lbs

Target Vessel

- Length: 20’ ¾”

- Height: 14’ 3/16”

- Width: 9’ 7/8”

- Weight: Approximately 79,000 lbs

Beam Dump

- Length: 24’ 11/16”

- Height: 21’ 3/8”

- Width: 12’ 1/4”

- Weight: Approximately 156,500 lbs

TIGHTEST TOLERANCES

- Flatness of .005

- Surface finish 16 micro

MATERIAL USED

- 304 SST

MATERIAL FINISH

- 16 micro

INDUSTRY FOR USE

- Research Rare Isotope Beam

IN PROCESS TESTING/INSPECTION PERFORMED

- Laser Tracker

VOLUME

- One unit

DELIVERY/TURNAROUND TIME

- 26 weeks ARO/ARM

DELIVERY LOCATION

- Michigan State University

STANDARDS MET

- Built Per Customers Specifications

SPECIAL FEATURES

- This unit.

NOTABLE

This unit highlights our ability to manufacture very large projects.

The client chose us based on our ability to manufacture very large projects.

Difficulties Overcome: Holding the flatness of usable condition and polishing O-ring grooves to a 16 micro.

Positive Client Feedback: The customer is please with our quality.

Special Feature of this Product: These parts require the ability to hold vacuum of 2 -7 torr.

Finished Product:

- Machinist

- Deburr/Polish

- Quality

CONTACT US

Our experts are ready to discuss our capabilities and your needs.

Project Gallery

Click on a photo to view a larger image.

Completed Project Photography

Magna Machine Company

11180 Southland Road

Cincinnati, OH 45240

Ph: 513.851.6900

© Magna Machine Co. All rights reserved.

Web site designed and maintained by Design-2-Part Web Design.