Large Part Manufacturing • Value-Added Services • Fully Functional Assemblies

Recent Projects

PROJECT TITLE:

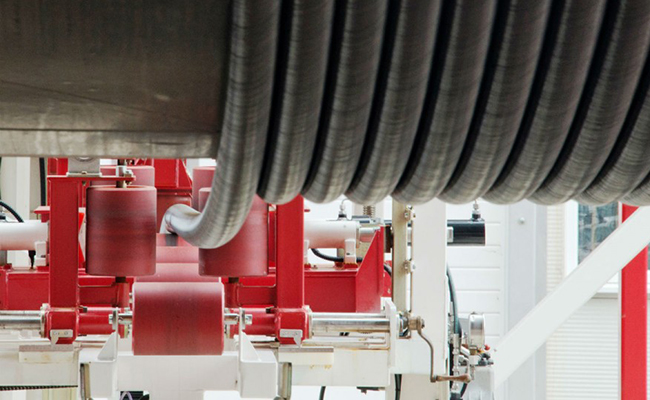

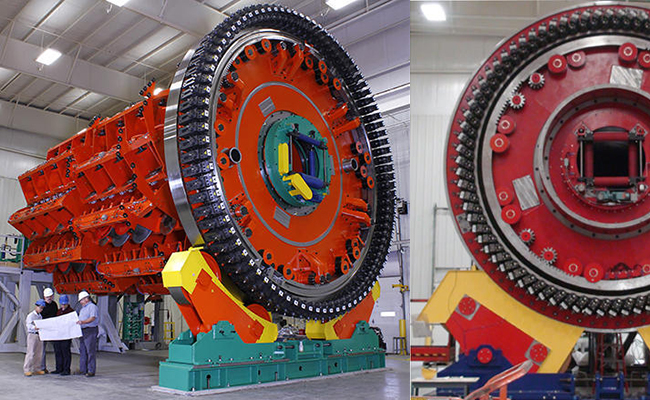

Tensile Armoring Machine

PROJECT DESCRIPTION:

The basic function of the Tensile Armoring Machine is to apply a layer of round or rectangular steel strip onto the flexible pipe being produced. The angle, speed and size of strip that is applied are determined by the flexible pipe specification. Tensile Armoring Machines are Rigid Stranders, meaning that the bobbins are always in the same relative position to the machine center line.

Two (2) machine cage sections are supplied to work in tandem. Each cage applies a layer opposite to the other and is supported by a rear bearing and front support disc. The rear bearing is designed to withstand the static and dynamic load of each cage along with the axial load provided by the wire tension. During machine operation, a pneumatic braking system is automatically adjusted as the bobbins unwind, compensating for the changing bobbin diameter and ensuring constant tension in the wire.

CAPABILITIES APPLIED/PROCESSES

Primary:

- Welding

- Milling

- Drilling

Secondary:

- Stress Relieve

- Turning

- Painting

EQUIPMENT USED TO MANUFACTURE PART

- Lathe

- Mill

- Welders

OVERALL PART DIMENSIONS

- Length: 245”

- Height: 160”

- Width: 55”

- Weight: 333,500 lbs

TIGHTEST TOLERANCES

- .0007”

MATERIAL USED

- High Strength Steel

MATERIAL FINISH

- 32-125

INDUSTRY FOR USE

- Tire and Rubber

- Oil and Gas

- Wire and Cable

IN PROCESS TESTING/INSPECTION PERFORMED

- NDT

- Laser inspection – Dimensional

VOLUME

- One unit

DELIVERY/TURNAROUND TIME

- 26 weeks

DELIVERY LOCATION

- East Coast, United States

STANDARDS MET

- Built Per Customers Specifications

SPECIAL FEATURES

- This unit.

NOTABLE

This unit highlights our ability to manufacture all phases of milling, turning, drilling and welding.

The client chose us based on other large work that they were happy with.

Difficulties Overcome: inside right angle work and in line boring over 10 feet apart.

Positive Client Feedback: The customer was pleased with the final product and will use us in the future.

Special Feature of this Product: This part stretched our abilities to the limit, including inside right angle work and in line boring over 10 feet apart.

Finished Product:

- Certified Welders and Machinists

CONTACT US

Our experts are ready to discuss our capabilities and your needs.

Project Gallery

Click on a photo to view a larger image.

Completed Project Photography

Magna Machine Company

11180 Southland Road

Cincinnati, OH 45240

Ph: 513.851.6900

© Magna Machine Co. All rights reserved.

Web site designed and maintained by Design-2-Part Web Design.